2023 Annual Sustainability Report

In 2023, PITT OHIO continued to be a leader in sustainability through innovations that improve efficiency and reduce emissions. Sustainability is important to PITT OHIO for many reasons: it is a differentiator from the competition, it supports our employee-centric strategy, and it creates efficiencies that save money. Click below to learn more about our investments in renewable energy, and the sustainable initiatives we've adopted to build an organization that is community-focused and purpose driven.

Click the image below to download PITT OHIO's 2023 Sustainability Report!

Now more than ever freight transportation emissions are on shippers’ minds.

With over 20% of U.S. carbon emissions stemming from medium and heavy-duty vehicles used in freight transport, the pressure is on. As shipment volumes are projected to surge 45% by 2040, the need for sustainable solutions is vital.

Emissions from freight transportation are classified as Scope 3 emissions. Under the European Union’s Corporate Sustainability Reporting Directive (CSRD) and California’s SB 253 reporting on Scope 3 emissions, including emissions from freight carriers, will be required. The critical next step for shippers is to identify carbon emissions across their supply chain in a way that is consistent, accurate, and actionable.

In 2023, PITT OHIO engaged with our customers in a variety of ways to collaborate on emissions tracking and reporting. At the same time, the business grew with new terminals, faster shipping lanes, and new equipment while continuing to reduce our carbon emissions. Below are highlights from this past year.

Scope 3 Emissions Reporting

In 2023 PITT OHIO hosted two Customer Summits to hear directly from our customers about their needs and challenges with calculating Scope 3 emissions from their supply chain. A key takeaway was the strong connection between sustainability and good business practices across various industries. Reducing carbon emissions often leads to reduced waste, ultimately improving process efficiency and cost savings. However, attendees also highlighted the complexities of identifying and managing Scope 3 emissions. There's a clear need for standardized and transparent methods for Scope 3 reporting.

Our discussions with shippers revealed a range of approaches to gathering Scope 3 emissions data. Customers were at various stages with some building their own model, leveraging the Smart Freight Centre’s Global Logistics Emission Council (GLEC) framework or using Smartway’s rankings. For those shippers that have not yet started calculating emissions, but are interested in understanding how to get started, we encourage them to utilize PITT OHIO’s CO2 Track reports which are generated using our carbon calculation.

PITT OHIO's carbon calculation goes beyond existing methods like Smartway and GLEC to provide a more accurate picture of your less-than-truckload (LTL) shipments. Our calculation leverages the routed miles and size in volume and weight to estimate fuel for all legs of the journey: pick up, linehaul, and delivery. PITT OHIO has been a leader in Scope 3 emissions reporting for nearly a decade. In 2023, we received a patent on this novel and improved processes for calculating emissions from less-than-truckload transportation.

We will continue to work with our customers to provide the data they need, in the format needed, so that we can help our valued customers meet requirements and also make the best business decisions.

Decarbonization

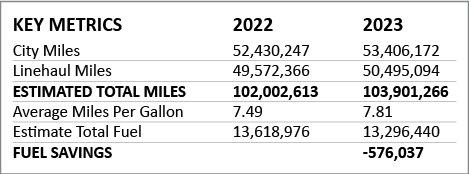

Sustainability is all about good business practices. Improving efficiency means eliminating waste. For PITT OHIO’s operation, that means more efficient routes and improved miles per gallon performance. As our business grew with four additional direct terminals, we also grew in shipments, tonnage and miles driven. At the same time, our Operation team used best practices in shifting, reduced idling, and using our diverse fleet profile to improve average miles per gallon by 4.3% while miles driven increased by approximately 2%.

Electric Trucks

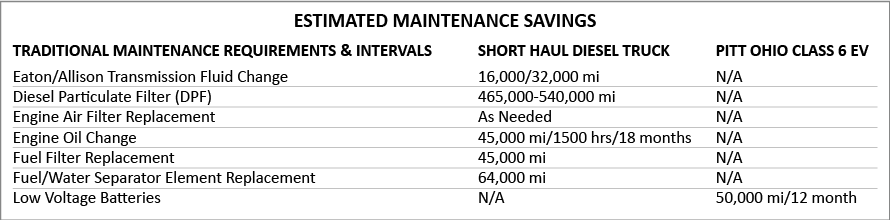

2023 was the first full year PITT OHIO operated Class 6 & 7 electric vehicles. The PITT OHIO team logged nearly 26,000 miles throughout the year. The biggest challenge to expanding the fleet with Battery Electric Vehicles (BEV) is the amount of power required from the electric utility grid. While BEVs will not be the complete solution for our operation, we see the value of electric trucks in our fleet with reduced maintenance costs and high marks from our drivers. Our strategy is to find the best solution at each facility which may include adding renewable energy generation, working with the local utility, and determining the best fleet mix, including alternative and renewable fuel powered vehicles. In 2024, we will begin work on our next electric vehicle charging installation in Harrisburg PA, with an estimated go live date for trucks in 2025.

People

PITT OHIO was selected as a Top Workplace in 2023 for the Pittsburgh PA, Washington PA, Columbus OH, Cincinnati OH, Cleveland OH, and Indianapolis IN terminals, as well as at our Pittsburgh PA corporate headquarters. The Top Workplaces lists are based solely on the results of an employee feedback survey administered by Energage, a leading research firm that specializes in organizational health and workplace improvement. Several aspects of workplace culture are measured including Leadership, Direction, Communication, Appreciation, Values and Health & Wellness. Employee retention remains high across the PITT OHIO organization. Overall turnover continued to be extremely low for the LTL industry. In addition, for the third year in a row, PITT OHIO was named One of America’s Best Midsize Employers by Forbes Magazine.

PITT OHIO is also committed to employee engagement and completed another bi-annual survey of all employees. Overall employee engagement continues to be very high, especially in our industry. Employee engagement is a key part of our service and our sustainability initiatives.

Early in 2024, PITT OHIO donated a 2018 Mack tractor to Forbes Road Career and Technology Center in order to strengthen the training of the next generation of diesel technicians. PITT OHIO partners with numerous cooperative learning programs across the region, providing students with valuable experience working alongside seasoned professionals at PITT OHIO facilities. Students get to apply theoretical knowledge to real-world scenarios, develop essential skills, and build their professional network. Three of the five cooperative learning students hired are from the Forbes Road program.

Giving Back to the Community

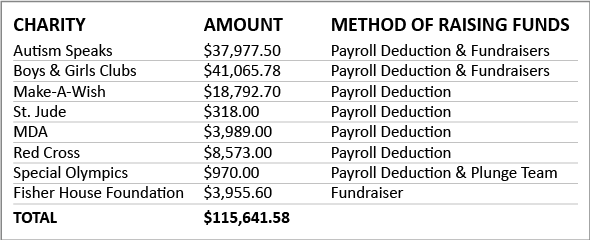

In 2023, PITT OHIO employees, and the company as a whole, gave to the following organizations:

Awards / Partnerships

- Ohio EPA Encouraging Environmental Excellence (E3) Program - Gold Level Award (second win)

- Parker Hannifin Sustainability Award (second win)

- Heavy Duty Trucking Magazine - 2023 Top Green Fleet Award

- Inbound Logistics Magazine - Green Supply Chain Partner 2023

- PITT OHIO Named 2023 Top Workplace in Cleveland, Columbus, and Cincinnati, OH, Indianapolis, IN and Pittsburgh and Washington, PA.

- Members of

- Ecovadis

- Carbon Disclosure Project

- Smartway

- Calstart

- Clean Fuels Ohio

- Pittsburgh Regional Clean Cities

- Drive Clean Indiana

- North American Council for Freight Efficiency (NACFE)

More information on PITT OHIO’s sustainability programs can be found at www.pittohio.com/sustainability, including our CO2 Track tool which allows customers to run their own carbon emission reports.